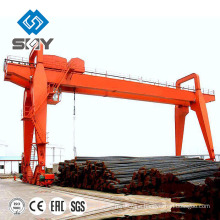

MG type double girder gantry crane price with mobile trolley, Top Quality Lifting Crane

Product Description

50t Double Beam Gantry crane, Top Quality Lifting Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50t Double Beam Gantry Crane, Top Quality Lifting Crane is specially designed for intensive container stacking due to its automation and less need and equipped with the different suspension parts. The crane combines maximum reliability and safety with high-operating efficiency, long-life, and low maintenance costs-leading to the lowest total cost of ownership. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technology parameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sketch of 50t Double Beam Gantry Crane, Top Quality Lifting Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product structure of 50t Double Beam Gantry Crane,Top Quality Lifting Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. Main girder of gantry crane | 2. Outrigger of gantry crane | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Be welded of steel plates with honeycomb hole, connected by high-strength precision bolt. There are sliding Rail for trolley to travel upper the girder which is fixed on outrigger by high-tension precision bolt. | a. Consist of rigid outrigger and flexible outrigger, all connection points are connected by high-tension bolt b. The ladder is used by operator to enter into cab or arriving at winch c. When the span>30m, there needs a flexible leg to reduce the lateral thrust of the trolley to the rail when the girder lifts materials. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. Traveling mechanism of gantry crane | 4. Trolley with Hoist of gantry crane | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| a. Consists of driving gear box and passive Wheel box b. The driving gear box supplies power to accomplish the crane’s traveling. What the difference between driving gear box and passive wheel box is that passive wheel box lacks transmission structure such as dynamo, Reducer and a pair of exposed gear. | The trolley are assembled with Motor, reducer brake, trolley frame, drum hook, pulley, rain cover and other parts. It includes lifting mechanism and cross traveling mechanism. The trolley is strictly designed according to the application and working environment.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5. Cabin of gantry crane | 6. Electrical system of gantry crane | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| a. Glass window can make the operator watch overview the all working condition and installed in the front and two sides of the cab b. As a group of independent cabinet , fixed outside of cab is connected by control Cable and linkage station which is set up in the cab. | a. Hoisting motor, long traveling motor and hydraulic power motor are included. The whole electrical system is controlled by PLC(programmable logic controller). b. Two operation mode : cabin and Remote control. c. Electric components are the top brand of Electric parts such as: Siemens, Schneider,etc. Or as your requirement. . | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7. Platform of gantry crane | 8. Plesase notice: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The platform is installed in order to maintain the crane, and the protective guard is added to protect the safety of staff | The wire ropes of trolley need to be examined regularly and changed in time if there is a 10% broken wires, loosen wires and wearing down. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application pics for the double beam gantry crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Safety protection 50t Double Beam Gantry Crane, Top Quality Lifting Crane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. Overload protection device is included. 2. Main lifting motor with thermal protection and current protection is equipped with. 3. Hooks with latch is to prevent goods fall down. 4. Top quality long time bearing polyurethane materials Buffer. 5. Protective earthling. 6. Crane switch and travel and end switch. 7. Emergency switch can stop all movement when any dangerous happened. 8. Sub-assemblies characteristics are tested before assembly. 9. All crane must be pre-assembled and tested before leaving factory and offer the certification of test. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Excellent After-sales service of our group | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. One year warranty for the whole machine from the test run day. 2. Free maintenance if problem occurs. And low charge for continue maintenance when warranty is expired. 3. Free quick-wear part provided. 4. Free training to end-users provided. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Our professional advice | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. Double or Single Girder Gantry Crane ? How to choose ? It depends on lifting capacity, working duty and frequency, working speed, loading dimension of the materials a. Usually below 20 tons with light or middle work duty you can use single girder. b. For wider span, faster working speed, or usually lifting larger equipments, Double Girder Gantry Crane is recommended. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.How to decide the suitable span for your crane ? According to the weight factor of crane, the span is required to made as short as possible. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. How to confirm the wheel distance A, meet the stability of crane while working. B, the loading materials can pass easily C, Generally speaking, wheel distance B=(1/4~1/6)S. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hope you to get a most suitable machine! | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Welcome to contact us by E-Mail or online, our professional reply is for you as soon as possible! | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certification | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Packaging & shipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Clients visit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Welcome to visit our company! | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Best quality and 24-hour service are always for you! | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Categories : Gantry Crane Series > Double Girder Gantry Crane

Premium Related Products