Double girder electric engine hoist work shop crane

Product Description

Guide to Overhead Cranes

YT CRANE has carefully arranged the various crane components for easy access, thus facilitating for preventative maintenance or service when required.

Crane Components details

Bridge - The main travelling structure of the crane which spans the width of the bay. The bridge consists of two end trucks and two bridge girders depending on the Equipment Type.

End trucks - Located on either side of the span, the end trucks house the wheels on which the entire crane travels. These wheels ride on the runway beam allowing access to the entire length of the bay.

Bridge Girder(s) - The principal horizontal beam of the crane bridge which supports the trolley and is supported by the end trucks.

Trolley Hoist - The unit consisting of both the hoist and the trolley frame. In situations where more than one hoist is required on one crane, both hoists can be supplied on a single trolley or on separate trolleys.

Trolley - The trolley carries the hoist across the bay along the bridge girders traversing the span.

Hoist - The hoist is mounted to the trolley and performs the actual lifting function via a Hook or lifting attachment. There are two basic types of hoist. The YT brand is a Wire Rope Hoist which is very durable and will provide long term, reliable usage.

Crane Classifications

The Crane Manufacturers Association of China has established 8 working classes to enable the purchaser to specify the most economical class of crane for a particular installation. It is uneconomical to either under specify or over specify when choosing a service class. Specifying a crane with too light a service class will reduce cost but may result in excessive maintenance. A crane with too high a service class may decrease maintenance costs but at an excessive initial investment.

Work class A3: light service

class A4 moderate service

class A5 heavy service

class A6 Severe service

class A7-A8: mill duty

Basic Terminology

Capacity - The maximum weight the crane will be required to lift.

Span - The horizontal distance between the rails of the runway on which the crane is to travel.

Lift or Hook Height - The required distance from the floor to the crane hook. This dimension is critical in most applications as it determines the height of the runway from the floor and is dependent on the clear inside height of the building.

Bridge, Trolley and Lift Speeds - The rate at which the bridge or trolley travels, or at which the hoist lifts, usually in meter per minute (MPM). You may specify either Single Speed or Two Speed travel/lift or a specific rate of speed,( 55208759,i.e. 80/30 MPM bridge travel). Another option as far a motion speeds are concerned is a Variable Frequency Drive. See the Control section for more information.

Equipment Types

This section specifies the kind of equipment you require. Overhead cranes come in four basic configurations;

Top Running (T/R) - The crane bridge travels on top of rails mounted on a runway beam supported by either the building columns or columns specifically engineered for the crane. (See the first and second graphics on the front of this pamphlet.)

Double Girder (D/G) - The crane consists of two end trucks, two bridge girders and the trolley hoist unit. The trolley runs on rails on top of the bridge girders. (See the first graphic on the front of this pamphlet.)

Control

Pendant - The pendant gives the operator precise control over the motions of the crane. There are many configurations of pendant depending on the functions of the equipment being controlled. Each pushbutton on the pendent controls an operating function of the crane.

VFD - A pendant can also be used in conjunction with a Variable Frequency Drive. A VFD is used to vary the frequency of the motors controlling the motions allowing for smooth acceleration and deceleration. The buttons on the pendant operate a VFD unit operated in much the same way as Two Speed control. The first step is held to maintain the current speed while the second step is used for acceleration. Deceleration is achieved by releasing the button entirely. Pressing the button back to the first step will maintain the new slower speed. It should be noted that the deceleration is not achieved through uncontrolled coasting but through a programmable dynamic braking system. The control provided by a VFD allows for a high level of customization.

Radio Control - The radio control performs exactly like the pendant but operates using a radio frequency. The radio control incorporates numerous safety features and allows the operator a greater range of operator motion than a pendant.

Power Supply –Design according to your building (220 -600Volts, 3 Phase, 50 or 60 Hertz).

Electrical equipment box: Siemens brand or Schneider Brand

Runway

The rails, beams and columns on which the crane operates. The Rail , on which the end trucks run, is fastened to the runway beam.

This beam is then supported on columns (Top Running) The existing building columns can be used or new ones can be supplied with the system. New columns can either be completely Free Standing or Tied Back to the existing building structure for additional lateral support. When designing a runway system that is to use existing building columns, it is important to provide the down shop center to center spacing between them. Conductors supply power to the crane and are mounted on the runway beam

YT CRANE will design and fabricate a crane runway system to specifically meet the needs of your application and environment with economy and safety in mind. Our runway systems are designed and certified by our in-house professional engineer. You may have an existing crane runway system and are thinking of adding another crane or verifying the integrity of the system for an increase in capacity and/or adding bays for and expansion. YTCRANE. can perform a comprehensive runway system analysis with a detailed report to assist in your facilities planning

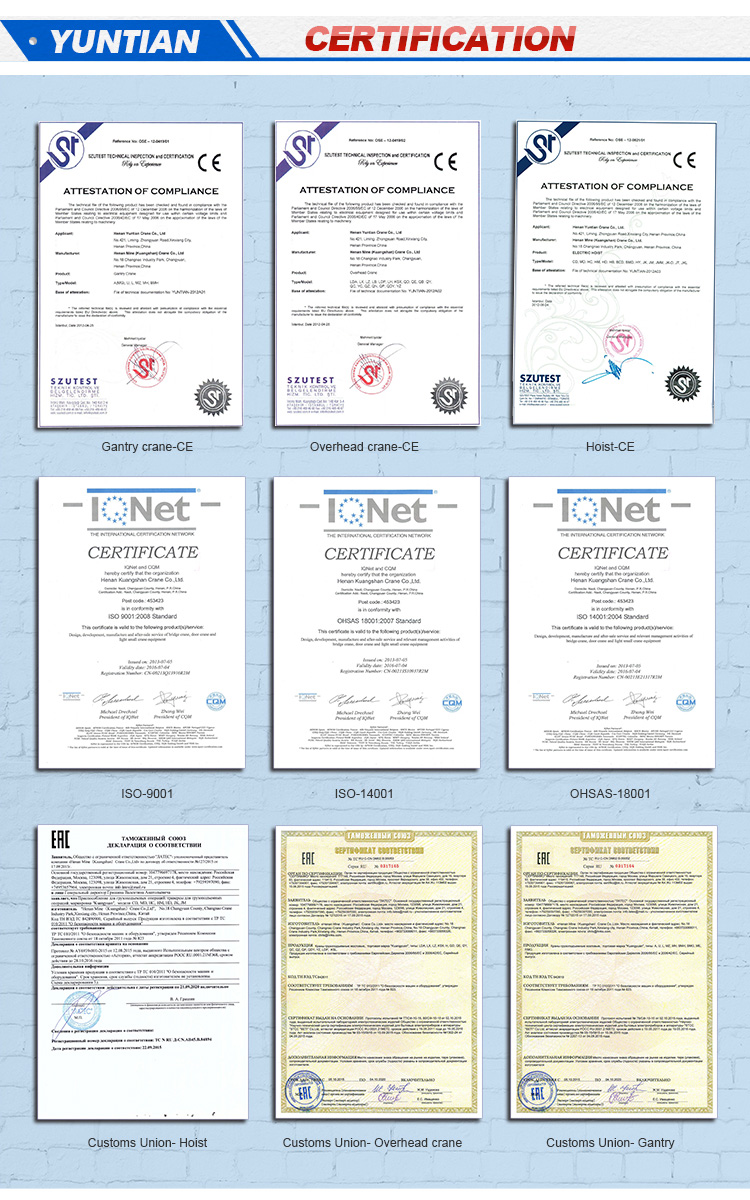

YunTian Group products meet the factory, workshop, port, mining, waste disposal, goods scattered, petrochemical, aerospace, military and other industries of universal Bridge Crane, Overhead Crane, eot crane, door crane, universal Gantry crane, rubber tyre and rail mounted container Gantry Crane four link type Portal Crane, quayside Container crane, crane, crane hook, mining Grab Crane, gantry crane, ship loader, grab bucket ship unloader, stacker reclaimer, dredger, mobile platforms and other types of hydraulic crane technical requirements.

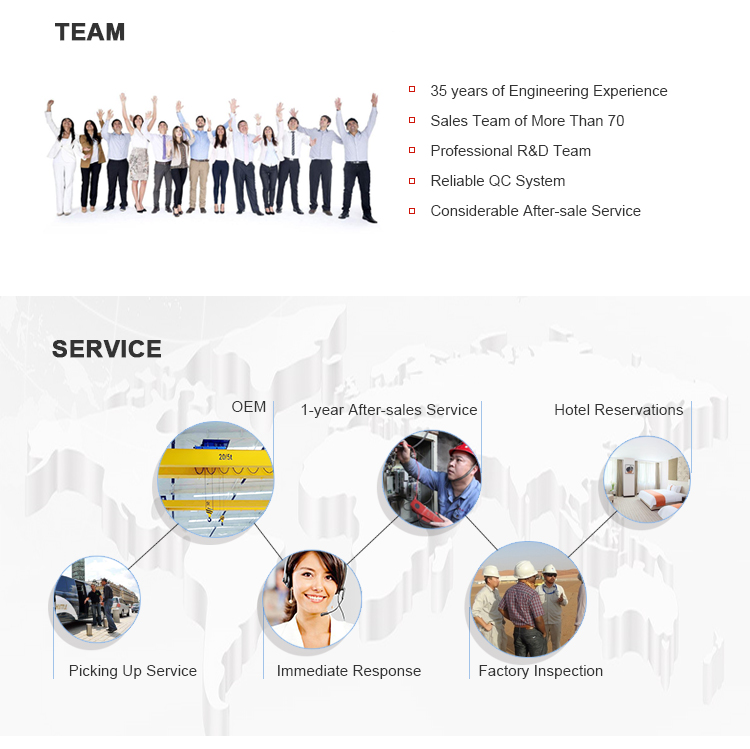

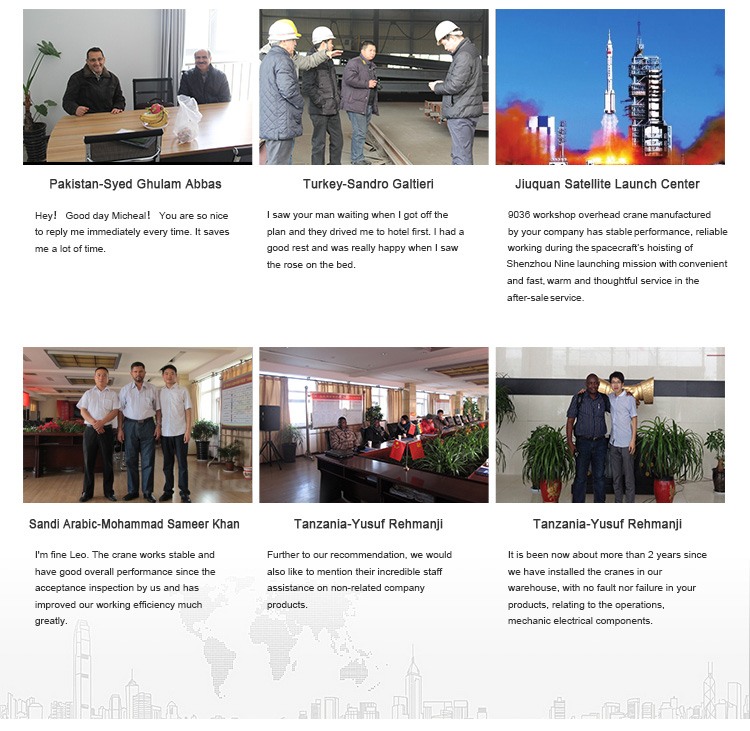

YunTian Group has a team of enthusiastic young people who treat every customer as their friend. Employees mutual help to service the customers from every detail. So you can get not only high quality products but personalized service.

“YunTian is a supplier worthy of cooperation!”

Oh, do we crack ourselves up?

NO! It's the customers' comments.

Thank you for your interests in Yuntian Group. Please feel free to submit your inquiry information to us. We love to talk and are not afraid to discuss any question about your crane, Hydraulic platform, hoist, winch need. Our sales manager will contact with you as soon as possible.

Just send your inquiry in the textbox below!

Product Categories : Overhead Crane Series > Double Girder Overhead Crane

Premium Related Products